Risk management is a collaborative effort

Collaboration is a powerful tool in reducing the risk of construction defect claims.

Collaboration leads to cooperation. That’s critically important in getting everyone, especially trades, to work with and not against each other.

We make sure everyone, from architects and engineers, to subcontractors and material suppliers, are “pulling on the same rope,” moving in the same direction.

It’s a collaboration that extends from pre-construction to post-project review, from project to project.

We build “partnerships” for success, a shared sense of project ownership. By sharing a common goal, and developing long-term relationships, we are all motivated to reduce the risk of construction defect claims.

We further foster collaboration by including project contributors in all major construction decisions and through financial incentives (through quicker payment, preferred scheduling, and repeat business).

Collaboration STARTS With Project-wide Inclusion

We involve all project participants in pre-construction meetings to:

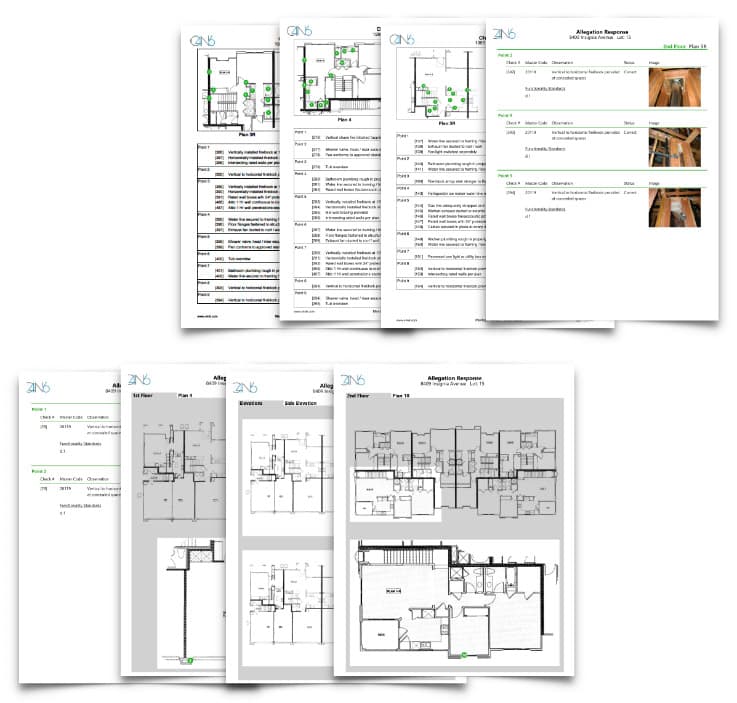

Every step is scrutinized, documented and reviewed

Documentation is vital to both minimizing risk and defending construction defect claims.

Useful documentation goes beyond a descriptive paper trail. It also offers prescriptive documents, which detail every project participant’s architectural and engineering plans, schedule, scope of work, responsibilities, financial agreements, insurance requirements, and QA/QC and safety expectations.

Our construction documents clearly assign accountability and confirm who is responsible for what. They also include specifications and installation manuals (digital and/or print). Together, the docs make up a “game plan” one that’s created months in advanced and prepares workers for various scenarios.

A comprehensive ‘Paper Trail’ Chronicles Daily Work

An independent, third-party constructive forensics specialist documents all project work before, during, and after work is completed.

Records include:

Standardization Reduces Risk

HOW WE DO ITContinuity Promotes Accuracy

HOW WE DO IT